ER385(904L)

Alloy ER 385 (904L) is used for welding materials of similar chemical composition, which are used for the fabrication of equipment and vessels for handling sulfuric acid and many chloride-containing media. This filler metal may also find applications for joining Type 317L material where improved corrosion resistance in specific media is needed. To reduce the propensity for fissuring and hot cracking, the low melting constituents such as carbon, silicon, and phosphorus are controlled to lower levels in this alloy.

ER385(904L)

Product Description:

Alloy ER 385 (904L) is used for welding materials of similar chemical composition, which are used for the fabrication of equipment and vessels for handling sulfuric acid and many chloride-containing media. This filler metal may also find applications for joining Type 317L material where improved corrosion resistance in specific media is needed. To reduce the propensity for fissuring and hot cracking, the low melting constituents such as carbon, silicon, and phosphorus are controlled to lower levels in this alloy.

Physical properties:

Density: 8.0g/m³

Melting point: 1300-1390 ℃

Extreme chemical composition:

Chemical Composition Limits | |||||||||

Weight% | C | Mn | Si | Cr | Ni | S | P | Mo | Cu |

ER 385 | ≤0.025 | 1-2.5 | ≤0.50 | 19.5-21.5 | 24-26 | ≤0.03 | ≤0.02 | 4.2-5.2 | 1.2-2 |

characteristic:

Highly austenitic stainless steel wire, characterized by its high resistance to stress corrosion cracking.

This alloy contains small amounts of the elements carbon, silicon, sulfur and phosphorus to reduce hot cracking and fracture.

Applications:

Pipeline segment

Agitators

Rotars

Used in the fabrication of equipment and vessels for handling and storage of sulfuric acid and phosphoric acid

Used for welding materials of similar chemical composition (Type 904L)

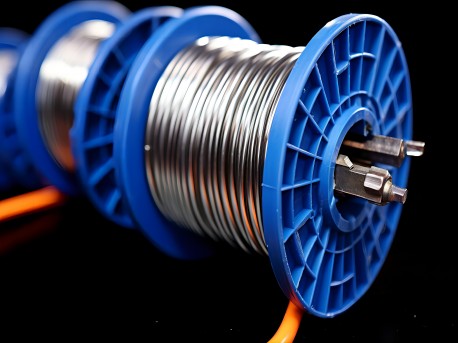

Form:

Straight Rods (TIG)-mm: 1.2-3.2

Spooled Wire (MIG)-mm: 0.8-1.2