45CT

45CT is coated on the surface of INCO-CLADR 671\800HT pipe. It can also be used for spray coating on carbon steel and stainless steel surfaces to form a corrosion-resistant surface layer of nickel-chromium alloys. The high chromium component provides excellent resistance to high temperature corrosion, including resistance to fuel dust atmospheres containing sulfur and vanadium.

45CT

Product Description:

45CT is coated on the surface of INCO-CLADR 671\800HT pipe. It can also be used for spray coating on carbon steel and stainless steel surfaces to form a corrosion-resistant surface layer of nickel-chromium alloys. The high chromium component provides excellent resistance to high temperature corrosion, including resistance to fuel dust atmospheres containing sulfur and vanadium.

45CT is a good spray material, used in working conditions with high protection requirements such as garbage incinerators and black liquor boilers.

Extreme chemical composition:

element | Ni | Cr | C | Mn | Fe | S | Si | Cu | Ti | P | Others |

content | Balance | 42-46 | 0.01-0.1 | ≤0.2 | ≤0.5 | ≤0.015 | ≤0.2 | ≤0.5 | ≤1 | ≤0.02 | ≤0.5 |

characteristic:

1. The surface of the coating prepared by it can form a layer of high-density Cr2O3 oxide film at high temperature, and its resistance to sulfide corrosion is 60 times that of carbon steel.

2. It can resist the erosion of corrosive (sulfur, vanadium) gases generated during boiler operation at high temperatures close to 980°C.

3. The thickness of the coating basically does not change after 24 months of use. The average erosion rate is <0.0127mm/year, which can extend the service life of the four tubes to more than 7 years.

4. The thermal expansion coefficient of the coating is similar to that of carbon steel, which can prevent the coating from falling off

Application areas:

Problems such as high-temperature oxidation, sulfide corrosion, and dust erosion of the four boiler tubes of thermal power plants (water wall tubes, super-heater tubes, re-heater tubes, and economizer tubes) have seriously affected the normal operation of thermal power plants for a long time. 45CT is a high-chromium nickel-based arc spray wire designed to solve the high-temperature corrosion and erosion of the four tubes of coal-fired boilers in thermal power plants and the serious high-temperature oxidation, sulfide corrosion and erosion of water-cooled wall tubes of black liquor boilers used in the paper-making industry.

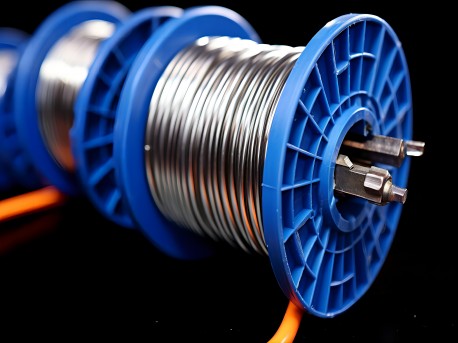

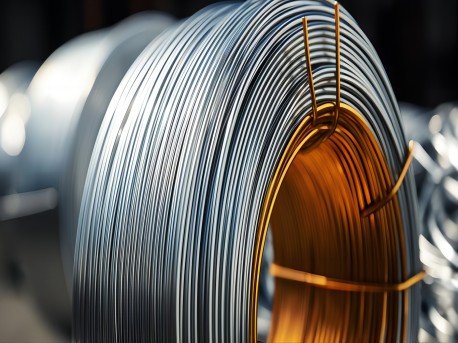

form:

1.6mm 2.0mm wire