Nickel200 (NO2200/2.4060)

Nickel 200 (UNS N02200/W.Nr. 2.4060 & 2.4066) is commercially pure (99.6%) wrought nickel. It has good mechanical properties and excellent resistance to many corrosive environments. Other useful features of the alloy are its magnetic and magnetostrictive properties, high thermal and electrical conductivities, low gas content, and low vapor pressure.

Nickel200 (NO2200/2.4060)

Nickel 200 (UNS N02200/W.Nr. 2.4060 & 2.4066) is commercially pure (99.6%) wrought nickel. It has good mechanical properties and excellent resistance to many corrosive environments. Other useful features of the alloy are its magnetic and magnetostrictive properties, high thermal and electrical conductivities, low gas content, and low vapor pressure.

Physical properties:

Density:8.89g/cm³

Melting point: 1440℃

Extreme chemical composition:

Nickel: balance

Iron: 0.4max

Carbon: 0.152max

Manganese: 0.35max

Sulfur: 0.01max

Silicon: 0.35max

Copper: 0.25max

characteristic:

1. Nickel 200 has natural acid and alkali corrosion resistance and is particularly useful under reducing conditions;

2. The alloy has excellent caustic alkali resistance, including its molten state. The alloy shows good resistance to acids, alkalis and neutral salt solutions;

3. Nickel 200 alloy can withstand all dry gases at room temperature. In dry chlorine and hydrogen chloride, Nickel Alloy 200 can be used at temperatures up to 550 °C.

Application areas:

Manufacture and handling of sodium hydroxide, especially at temperatures above 300 °C;

Production of viscose fiber. Soap manufacturing.

Production of aniline hydrochloride and chlorination of aliphatic hydrocarbons such as benzene, methane and ethane.

Manufacture of vinyl chloride monomer.

Reactors and vessels for generating fluorine and reacting with hydrocarbons.

form:

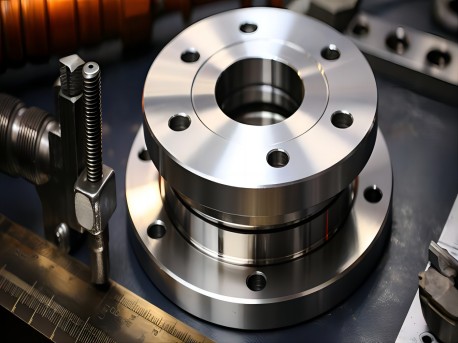

Forgings, plates, bars, tubes, strips and wires