Inconelx-750/UNS NO7750/GH4145

Inconel High strength, good relaxation resistance below 540℃, and good formability and welding performance. The alloy is mainly used to manufacture relaxation-resistant flat springs and coil springs for aircraft engines that operate below 800°C and require high strength. It can also be used to manufacture turbine blades and other parts of steam turbines.

Inconelx-750/UNS NO7750/GH4145

Product Description:

Inconel High strength, good relaxation resistance below 540℃, and good formability and welding performance. The alloy is mainly used to manufacture relaxation-resistant flat springs and coil springs for aircraft engines that operate below 800°C and require high strength. It can also be used to manufacture turbine blades and other parts of steam turbines.

Physical properties:

Density: 8.28g/cm³

Melting point: 1393-1427℃

Extreme chemical composition: %

Nickel: 70min

Chromium: 14-17

Iron: 5-9

Niobium + Tantalum: 0.7-1.2

Carbon: 0.08max

Cobalt: 1.00max

Manganese: 1.0max

Silicon: 0.5max

Sulfur: 0.01max

Phosphorus: 0.015max

Aluminum: 0.4-1.0

Titanium: 2.25-2.75

Copper: 0.5max

Characteristic:

It has good corrosion resistance and oxidation resistance below 980℃, high strength below 800℃, good relaxation resistance below 540℃, and also has good formability and welding performance.

Application areas:

This alloy is mainly used to manufacture corrosion-resistant planar wave springs, circumferential spiral springs, spiral compression springs, spring clamps and sealing rings for aerospace engines with operating temperatures below 540°C.

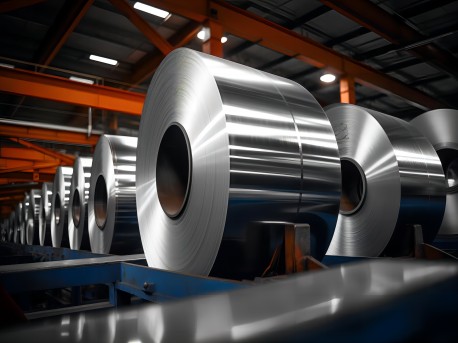

Forms:

Bars, forgings, rings, hot rolled plates, cold rolled plates, strips, tubes and wires