Inconel600/UNS NO6600/NS312

It has the combined properties of toughness and corrosion resistance. Because it also has high strength and good oxidation resistance at high temperatures, it can also be used in the heat treatment industry to manufacture various structural parts. In the nuclear power industry, it has good resistance to high temperature and high pressure water, so it is also an important structural material for pressurized water reactor nuclear power plants. When used for evaporator heat exchange tubes, Inconel600 tube production requires not only solid solution treatment, but also medium-temperature desensitization treatment, and the residual stress in the small R section of the U-shaped tube needs to be removed. It can also be used for pressurized water and the upper and lower heads of osmotic reactors.

Inconel600/UNS NO6600/NS312

Description:

It has the combined properties of toughness and corrosion resistance. Because it also has high strength and good oxidation resistance at high temperatures, it can also be used in the heat treatment industry to manufacture various structural parts. In the nuclear power industry, it has good resistance to high temperature and high pressure water, so it is also an important structural material for pressurized water reactor nuclear power plants. When used for evaporator heat exchange tubes, Inconel600 tube production requires not only solid solution treatment, but also medium-temperature desensitization treatment, and the residual stress in the small R section of the U-shaped tube needs to be removed. It can also be used for pressurized water and the upper and lower heads of osmotic reactors.

Due to its corrosion resistance, heat resistance, good curing performance and good workmanship, it is widely used in various industries. It has good corrosion resistance in fresh water and fluctuating sea water, but may cause corrosion in still sea water. It has high corrosion resistance to various alkaline solutions and most organic acids and compounds, and is not prone to stress corrosion cracking. However, it is prone to stress corrosion cracking under conditions of high concentration of caustic alkali or high temperature mercury.

Limiting Chemical Composition, %

Ni: ≥72

Cr: 14-17

Fe: 6-10

C: 0.15max

Mn: 1max

Si: 0.5max

S: 0.015max

P: 0.015max

Cu: 0.5max

Features

1. It has good resistance to reduction, oxidation and nitrogen medium corrosion.

2. Good resistance to stress corrosion cracking at room temperature and high temperature

3. Good corrosion resistance to dry chlorine gas and hydrogen chloride gas

4. It has good mechanical properties at zero, room temperature and high temperature.

5. It has good creep rupture strength and is recommended for use in working environments above 700°C.

Application areas

Aerospace components

Chemical processing - chlorination equipment, fatty acids, hydrofluoric acid, hydrogen chloride, sulfuric acid, neutral and alkaline salt solutions, vinyl chloride monomer, sodium sulfide, titanium dioxide

Food processing

Petrochemical Processing-Catalyst Re-generator

Power Generation - Nuclear Components

Paper-making-rosin acid equipment

Thermal Treatment - Baskets and Trays, Boxes, Insulation and Annealing Furnaces, Nitriding Container, Roller Furnaces, Vacuum Furnace Components

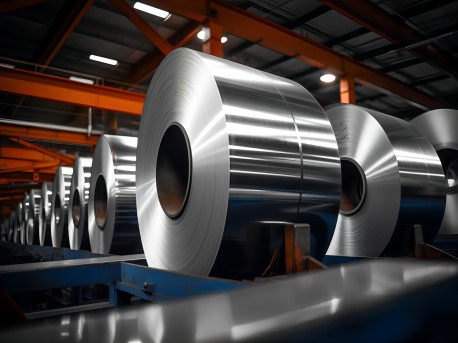

Form: sheet, strip