IncoloyA-286

This age-hardenable iron-nickel-chromium alloy is designed for applications requiring high strength and good corrosion resistance at temperatures up to 700°C (1290°F). The strength of incoloy® A286 makes it ideal for a variety of components in aircraft and industrial gas turbines. The alloy is also used in the offshore oil and gas industry, and in fastener applications for automotive engine and manifold components that are exposed to high heat and stress.

IncoloyA-286/ UNS S66286/W.Nr.1.4980

Product Description:

This age-hardenable iron-nickel-chromium alloy is designed for applications requiring high strength and good corrosion resistance at temperatures up to 700°C (1290°F). The strength of incoloy® A286 makes it ideal for a variety of components in aircraft and industrial gas turbines. The alloy is also used in the offshore oil and gas industry, and in fastener applications for automotive engine and manifold components that are exposed to high heat and stress.

Physical properties:

Density:8.14g/cm³

Melting point: 1430℃

Extreme chemical composition:

Nickel: 24.0-27.0

Chrome: 13.5-16.0

Iron: balance

Molybdenum: 1.0-1.5

Vanadium: 0.1-0.5

Carbon: 0.03-0.08

Manganese: 1.0-2.0

Silicon: 0.5max

Sulfur: 0.015-0.02

Boron: 0.001-0.01

Titanium: 1.75-2.35

Phosphorus: 0.03max

Copper: 0.25max

Aluminum: 0.4max

characteristic:

l High strength and good corrosion resistance at high temperatures

l Age hardenable

l Suitable for high temperature fasteners

l High temperature static applications

Application areas:

Jet engine

super charger

Afterburner parts

Fastener

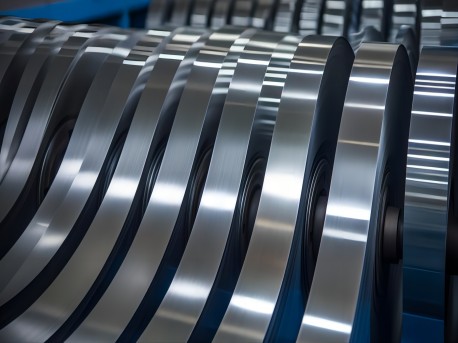

Form:

Seamless pipes, steel plates, round steel, forgings, flanges, rings, welded pipes, steel strips, wires and supporting welding materials.