Hastelloy C-276

C-276 alloy is a nickel-chromium-molybdenum alloy that offers universal corrosion resistance unmatched by any other alloy. C-276, also known as Inconel® C-276 or Hastelloy® C-276, is an improved variant of Alloy C because it generally does not require solution heat treatment after welding and greatly improves machinability

Hastelloy C-276 (UNS N10276/W.Nr. 2.4819)

Product Description:

C-276 alloy is a nickel-chromium-molybdenum alloy that offers universal corrosion resistance unmatched by any other alloy. C-276, also known as Inconel® C-276 or Hastelloy® C-276, is an improved variant of Alloy C because it generally does not require solution heat treatment after welding and greatly improves machinability. This alloy resists the formation of grain boundary precipitates, especially in the weld heat affected zone. This characteristic makes C-276 alloy suitable for use in the welded state.

Physical properties:

Density: 8.9g/cm³

Melting point: 1325-1370℃

Extreme chemical composition:

Alloys | % | Ni | Cr | Fe | Mo | C | Mn | Si | S | P | Co | V | W |

Hastelloy C | min | balance | 14.5 | 4 | 15 | 3 | |||||||

max | balance | 16.5 | 7 | 17 | 0.08 | 1 | 1 | 0.03 | 0.04 | 2.5 | 0.35 | 4.5 | |

C276 | min | balance | 14.5 | 4 | 15 | 3 | |||||||

max | balance | 16.5 | 7 | 17 | 0.01 | 1 | 0.08 | 0.03 | 0.04 | 2.5 | 0.35 | 4.5 |

The minimum mechanical properties of the alloy at room temperature:

Typical mechanical properties | Tensile Strength Rm N/m㎡ | Yield Strength RP0.2 N/ m㎡ | Elongation A5% |

Solution treatment | 690 | 283 | 40 |

characteristic:

Alloy C-276 has excellent resistance to both localized corrosion and oxidizing or reducing media.

Application:

It is used in chemical processing, pollution control, pulp and paper production, industrial and municipal waste treatment, and recovery of "sour" natural gas. Air pollution control includes stacks, ducts, dampers, scrubbers, stack gas re-heaters, fans and fan housings. In chemical processing, alloys are used in components including heat ex-changers, reactor vessels, evaporators, and transfer piping.

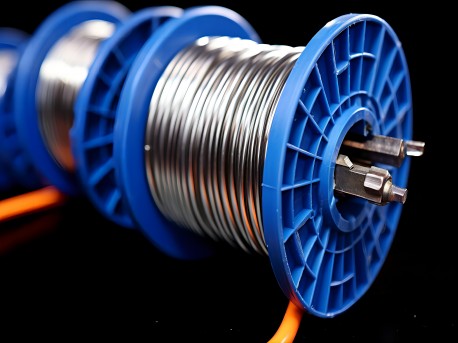

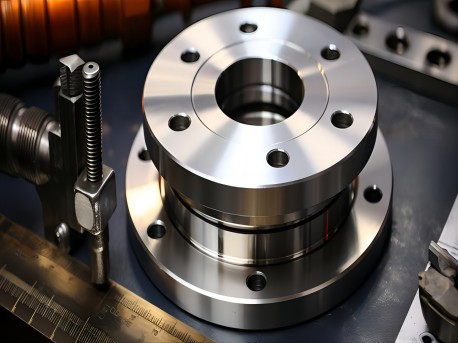

Form: rod, plate, tube, flange, strip, wire, forging