Elastic alloy is a type of precision alloy and is used to make elastic components such as elastic sensitive components, energy storage components and frequency components in precision instruments. In addition to good elastic properties, it also has non-magnetic properties, high resistance to micro-plastic deformation, high hardness, low resistivity, small temperature coefficient of elastic modulus, and low internal friction.

Elastic alloys include highly elastic alloys and constant elastic alloys. The former has high elastic limit, low an-elastic effect and good heat resistance; the latter has an elastic modulus that hardly changes with temperature within a certain temperature range, and is also called "Elinvar alloy".

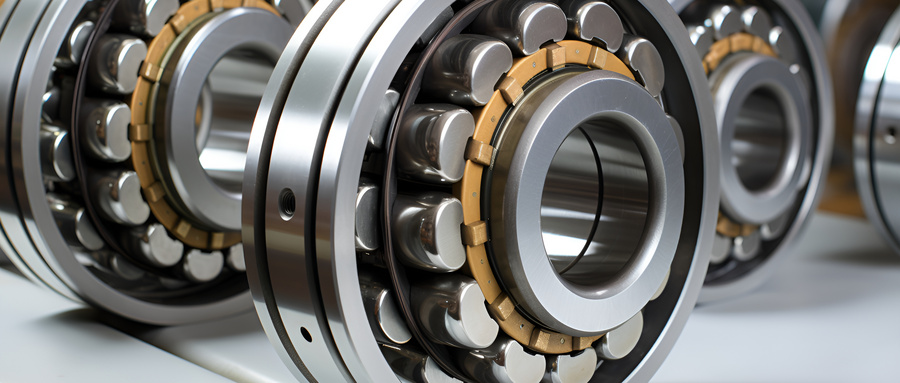

Highly elastic alloys are mainly used for elastic sensitive components such as diaphragms, diaphragms, torsion bars, energy storage components such as springs and instrument bearings.

With the development of amorphous metal materials, a series of amorphous alloys have been found to have constant elastic properties, which has attracted people's attention. Constant elastic alloy is mainly used for hairsprings, suspension wires, diaphragms, mechanical filters, standard frequency components, delay lines, etc.

Production Process

If vacuum smelting is used, those with special requirements for micro-structure must use double vacuum smelting, that is, the cast electrodes are smelted in vacuum and then remelted in a vacuum consumable furnace or electroslag furnace to produce steel ingots with low gas inclusions.

The heating temperature before forging and rolling is generally 1150~1200℃, and the final processing temperature is not less than 900℃. The shrinkage cavities of elastic alloy ingots are generally deep and must be paid attention to during forging and rolling.