Jintai Alloy Material

Supply Alloy Material To Any Industry

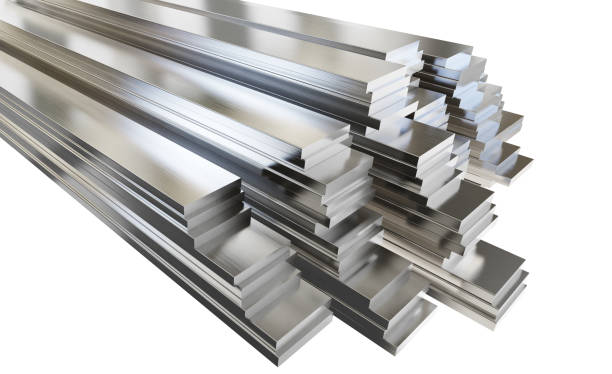

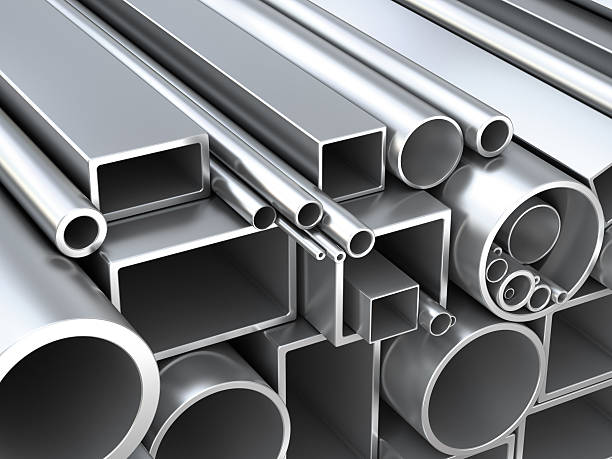

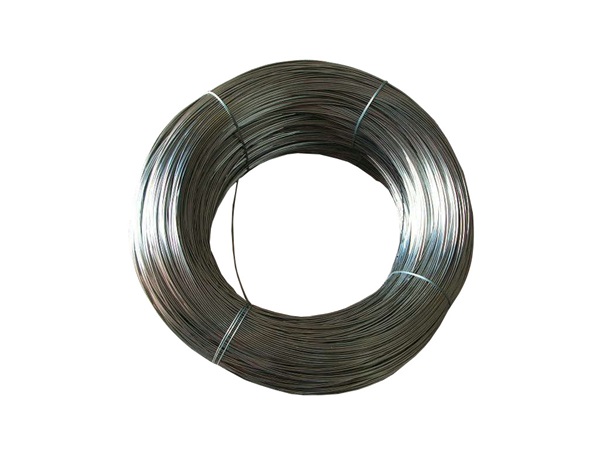

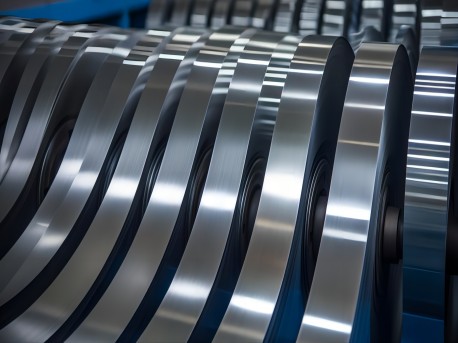

Jintai Alloy offers a one-stop Alloy Material solution to any industry. We can provide custom services according to your dimensions, sizes, surface finish, grades, and more options.

What Clients Say About Jintai Alloy Metal

-

Hi! I am Michael from Mexico. I have a Alloy fabrication company dealing with kitchen tops, doors, windows, and tower masts. Good thing, I have found Jintai Alloy Metal as my supplier of Alloy materials. Their products are in good-quality. Plus, I can also choose specific grades for my fabrication needs.Micheal From Mexico

Hi! I am Michael from Mexico. I have a Alloy fabrication company dealing with kitchen tops, doors, windows, and tower masts. Good thing, I have found Jintai Alloy Metal as my supplier of Alloy materials. Their products are in good-quality. Plus, I can also choose specific grades for my fabrication needs.Micheal From Mexico -

Good day! I am Stephen from America. My company deals with fabrication of Alloy structural columns and beams. Sourcing Alloy materials with a very good quality is very difficult nowadays. Luckily, Jintai Alloy Metal has helped me. We have been partners now for more than three years. Thank you, Jintai Alloy Metal.Stephen From America

Good day! I am Stephen from America. My company deals with fabrication of Alloy structural columns and beams. Sourcing Alloy materials with a very good quality is very difficult nowadays. Luckily, Jintai Alloy Metal has helped me. We have been partners now for more than three years. Thank you, Jintai Alloy Metal.Stephen From America -

Thank you, Jintai Alloy Metal for providing my company with excellent quality Alloy sheets for my metal fabrication services. My customers loved all the Alloy parts and we received a very good feedback.Rita From Frence

Thank you, Jintai Alloy Metal for providing my company with excellent quality Alloy sheets for my metal fabrication services. My customers loved all the Alloy parts and we received a very good feedback.Rita From Frence -

Jintai Alloy has been my business partner and Alloy material supplier for over two years now. Throughout the years, they never failed to provide us with good quality Alloys sheet for our fuel tank fabrications. Plus, their services and after-sales support are awesome.Greg From Germany

Jintai Alloy has been my business partner and Alloy material supplier for over two years now. Throughout the years, they never failed to provide us with good quality Alloys sheet for our fuel tank fabrications. Plus, their services and after-sales support are awesome.Greg From Germany

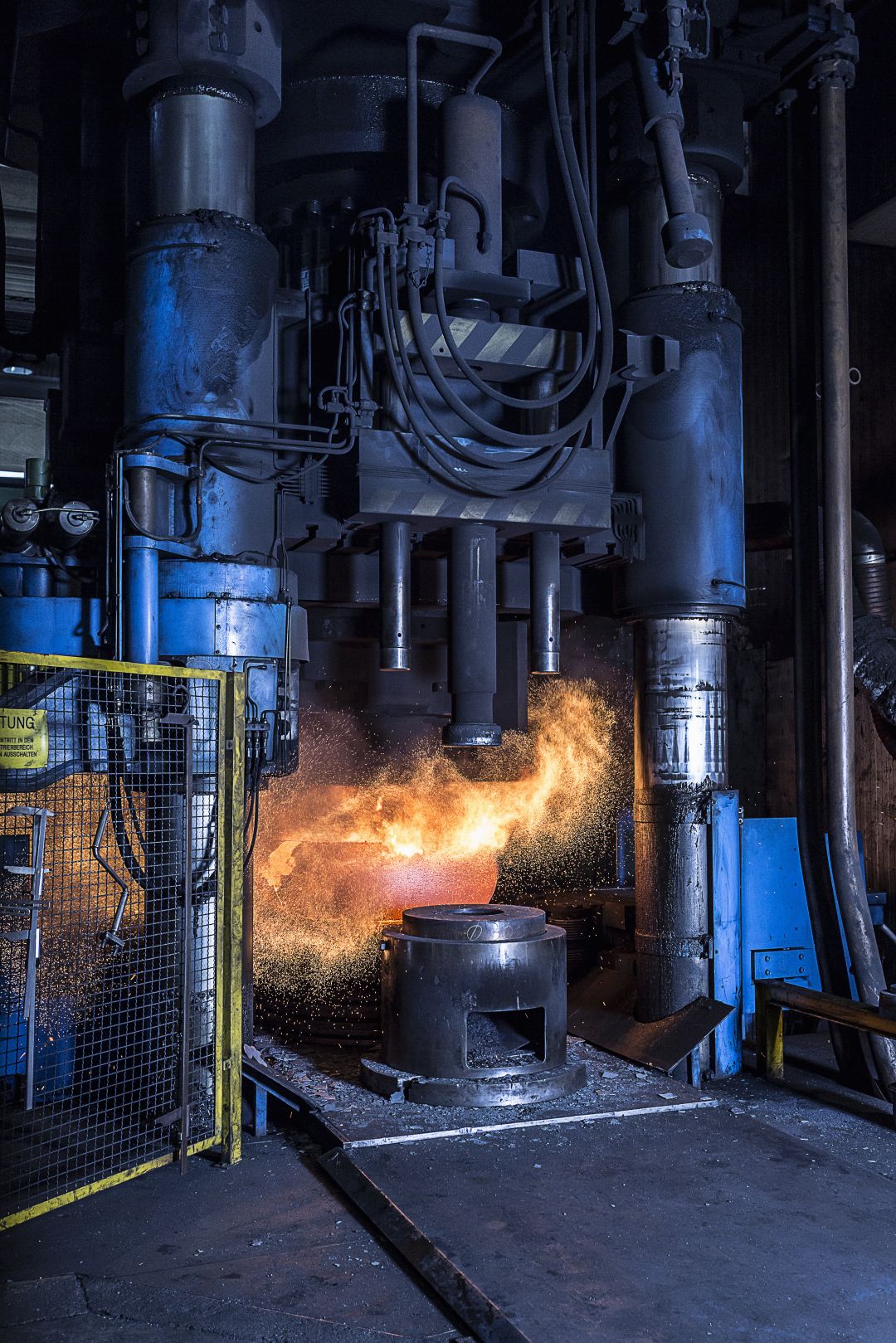

One-Stop Alloy Material Manufactory

We produce Alloy materials according to your specifications. You can contact us for your desired grades selection, thickness, surface treatments, and dimensions. Just send us your details today.

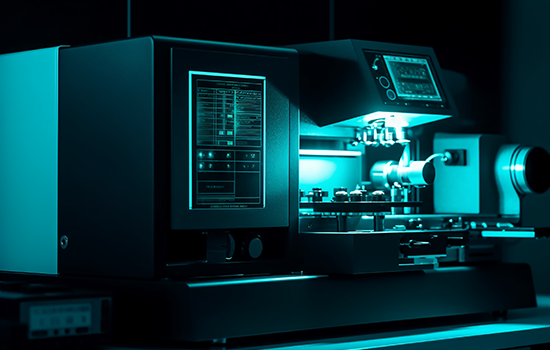

Our quality inspection department uses XRF fluorescence spectrometer to analyze and test the composition of each batch of alloy materials produced to ensure that the finished product meets the special requirements of customers.

All our Alloy materials are certified by different industry standards such as ISO9001:2015, ROHS environmental standards, ISO14001:2014, AAA Certification, CQGC Certifications, and more. Our professional QC team also performs strict and 100% inspection on all production stages.

Our support and services are not only limited from the beginning of our transactions. Even if you have received your orders, Jintai Alloy will continue to provide excellent after-sales services. We will continue providing assistance and warranty to your orders.

Resource From The Blog

As a responsible manufacturer, we understand the importance of maintaining high quality standards and protecting the environment. That's why we strictly adhere to ISO 9001:2015 and ROHS environmental standards in all aspects of our operations. The ISO 9001:2015 certification demonstrates our commitment to quality management and ensures that our products and services consistently meet customer requirements and regulatory standards.

In today's fast-paced technological landscape, precision alloys stand as the unsung heroes behind many groundbreaking innovations. As a leading manufacturing enterprise specializing in specialty alloys, we take pride in our expertise in precision alloy manufacturing. These alloys are meticulously engineered to possess exceptional mechanical, physical, and magnetic properties, making them indispensable in a wide range of high-precision applications.

As a responsible manufacturer, we understand the importance of maintaining high quality standards and protecting the environment. That's why we strictly adhere to ISO 9001:2015 and ROHS environmental standards in all aspects of our operations. The ISO 9001:2015 certification demonstrates our commitment to quality management and ensures that our products and services consistently meet customer requirements and regulatory standards.

More Questions You May Have

Yes,Jintai is subordinate to Danyang Jintai Alloy Materials Co., Ltd, which was established in 2018, specialized in manufacturing the nickel based alloys, and located in Jiangsu Province, that is near to Shanghai & ningbo port.

Usually the lead time is around 25-30 days. According to different purchase quantities and requirements, our production cycle and lead time will also be adjusted accordingly. However, no matter the quantity is large or small, or the value of the goods, we will strictly control every production link to ensure product quality.

As a factory, we have channels to obtain raw materials with more competitive prices, and we can control every production link to ensure product quality. In addition, the city's personnel and equipment costs are relatively low, and both logistics and warehousing have obvious advantages compared with Shanghai and some domestic big cities.

It's the best way that if you can inform us of the your required product such as material, surface, form and size, so that we can customize it for you.

Sure,we can provide OEM and ODM services. You just need to prepare your steel grade and tell us, we will get it.